Air compressors are vital cogs in the machinery of multiple industries. A well-maintained compressor ensures smooth operational flow, but a faulty one can be a bottleneck, draining both time and resources. Therefore, understanding air compressor problems and knowing how to fix air compressors are skills worth mastering.

Understanding Your Air Compressor

What is an Air Compressor?

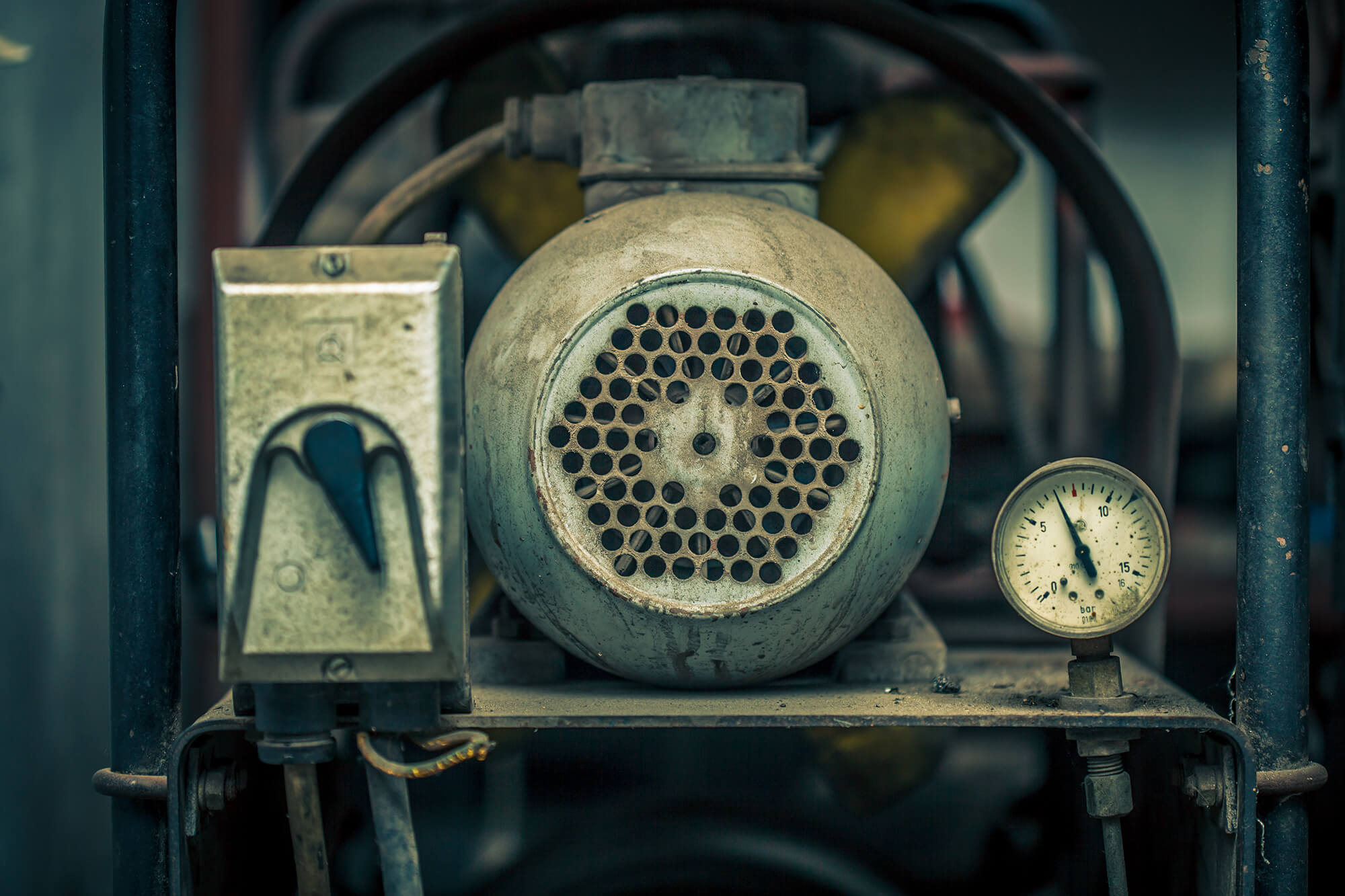

An air compressor is a mechanical device that enhances the pressure of air by reducing its volume. It has several key components such as an air intake, pressure switch, air filters, and a pressure gauge, which make up the compressed air system. Understanding these parts can facilitate easier air compressor troubleshooting and repair.

The Role of Air Compressors in Different Industries

From automotives to healthcare, air compressors are indispensable. They power pneumatic tools, help in manufacturing processes, and even have a role in medical procedures. Given their ubiquity, air compressor maintenance tips are useful across a wide array of vocational specialities.

Air Compressor Troubleshooting: Common Air Compressor Problems

Faulty Pressure Release Valve

A faulty pressure release valve can lead to the compressor lacking sufficient air pressure. It’s crucial to identify this early on to prevent any operational issues, replacing the valve as necessary. A sign that you need a new valve is that your compressor may not be able to build up sufficient air pressure. This can be checked by monitoring the pressure gauge.

Loose Compressor Floor Mounting

Over time, the compressor floor mounting may become loose, leading to increased vibrations and noise. Tightening or replacing the floor mounting hardware will usually resolve this issue, reducing unnecessary wear and tear on the machine.

Air Leaks

Air leaks are another common problem that can lead to reduced efficiency and power. You may even hear a hissing sound from the compressor when it’s not running. Regular maintenance, including inspecting for leaks and ensuring all air compressor parts are tightly sealed, is necessary to prevent this issue. If this problem is identified, you will need to find the location of the leak and replace the affected part, often a seal or valve.

Worn Piston Rings

Worn piston rings can significantly affect your compressor’s power supply and output. If you notice a drop in efficiency, inspect the piston rings and consider replacing them.

Blown Cylinder Head Gasket

A blown cylinder head gasket can cause your air compressor to overheat, resulting in an excessive discharge air temperature and premature shut down. If this is the case, replacing the cylinder head gasket is a necessary step to resolve the problem.

Compressor Air Intake Restricted

The compressor air intake can become restricted over time, usually due to a clogged air filter. You should be able to hear this issue with a whistling or choking sound, and it might take longer than usual to pressurise. To fix this, consider replacing or cleaning the air filter or the air cleaner element to ensure optimal performance of your air compressor.

Wrong Oil Viscosity

Using oil with the wrong viscosity can negatively impact the functioning of your air compressor, potentially leading to overheating and mechanical wear. Besides noticing that your compressor may be running hot, you might also see that the oil is running too thick or thin. Regularly checking and maintaining the correct oil levels and viscosity can keep your compressor running smoothly.

Inadequate Air Delivery

Sometimes, your air compressor may struggle to deliver adequate air for your operational needs. This problem could be due to worn-out compressor parts, clogged air filters, or an issue with the pressure release valve. Your air tools may not work correctly, appearing underpowered or erratic. Regular maintenance and checking of compressor parts, cleaning or replacing the air filter, and checking the pressure release valve can resolve this issue.

Moisture in the Compressed Air

In humid conditions, the air compressor can draw in moisture, which then condenses and collects in the air tank. Too much moisture can lead to water in the air lines or rust inside the air tank, so it’s important to regularly drain the air tank and use proper air dryer systems.

Over-pressurisation

Over-pressurisation happens when the compressor exceeds its maximum pressure, risking a dangerous explosion. This is often caused by a malfunctioning pressure switch. If the switch is faulty, it’s crucial to replace it to ensure safety and efficient operation.

Low Tank Pressure and the Unloader Valve

One frequent issue is that of low tank pressure, often attributable to a faulty unloader valve. You may notice the tank pressure isn’t building as it should. A DIY air compressor repair option is to inspect and, if needed, replace the unloader valve.

Loose Mounting and Vibration Pads

Increased vibrations and noise often stem from loose compressor floor mounting. Installing vibration pads and ensuring the compressor is properly mounted can be an effective fix.

Excessive Oil and Oil Leaks

Oil leaks or excessive oil consumption could indicate an issue with the machine’s oil separators or may suggest a need for a new valve plate. Regular checks can prevent this issue from escalating.

Electrical Power and Safety Measures

Your compressor’s electrical power supply is another critical area for monitoring. Check the power connections and ensure the safety valve and power switch are both functioning as they should.

Motor Shuts Down Too Soon

If your motor shuts down before reaching the cut-off point, this might signal issues with the power supply or the pressure switch. Investigate these areas for a DIY fix.

Cut-in and Cut-off Pressures

Ensure that the cut-in and cut-off pressures are set correctly. Incorrect settings can cause operational inefficiencies.

Knowing these common problems can help you with air compressor troubleshooting and provide a better understanding of when professional help might be necessary. Remember, regular air compressor maintenance is essential to keep your unit in peak condition and prolong its lifespan.

Professional Air Compressor Repair Services: When to Seek Help

If you encounter persistent issues despite your best troubleshooting efforts, it’s time to call in professionals. Expert technicians can perform a thorough inspection, diagnose complex issues, and provide necessary repairs or replacements. Proper repair services can significantly extend your air compressor’s lifespan.

Ensuring Optimal Air Compressor Performance

Regular air compressor maintenance and prompt identification of signs of failure are key to ensuring optimal performance. By understanding common problems and seeking professional assistance when needed, you can keep your air compressor running efficiently, minimise costly breakdowns, and maximise its lifespan. Take proactive measures to maintain your air compressor and enjoy its reliable operation for years to come.

Should you need any replacement parts, don’t hesitate to visit Express Australia’s online store, your trusted source for quality air compressor parts.

Check the oil level frequently and refill as needed. The wrong oil level can result in inadequate lubrication and increased wear and tear.

Clean or replace air filters regularly to ensure unobstructed air intake. Dirty filters can restrict air flow and reduce efficiency.

Frequent draining is essential, especially in humid conditions, to prevent moisture build-up in the air tank.

Safety components like the safety valve and pressure regulator should be checked regularly to ensure they are functioning correctly.