COMPRESSED AIR EQUIPMENT 1300 446 944

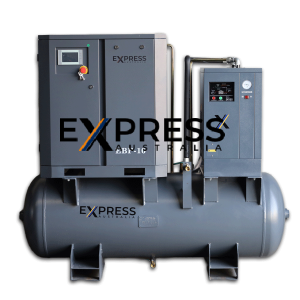

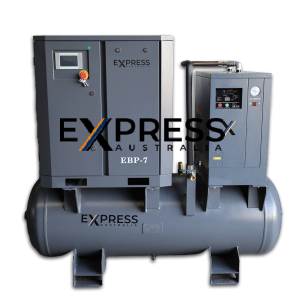

Rotary screw air compressors are a reliable and efficient solution for industries requiring consistent, high-quality compressed air. Capable of continuous airflow and pressurisation, these compressors provide a steady air supply without the downtime associated with other types of compressors. Whether you’re managing a manufacturing plant, operating a construction site, or overseeing a food packaging facility, a rotary screw air compressor offers the power and efficiency you need to keep operations running smoothly.

Unlike traditional piston compressors, screw air compressors use two rotors that rotate in opposite directions to compress air efficiently. This design minimises wear and tear, reduces energy consumption, and ensures a more stable air pressure output. With their ability to operate in demanding environments and extreme temperatures, screw compressors are ideal for a wide range of industrial applications. Additionally, their quiet operation, energy-efficient performance, and low maintenance requirements make them a preferred choice for businesses looking to optimise their air compression needs.

-

Stock Available On Request

-

Stock Available On Request